Timing maintenance is a very important work for all equipment, which is the fundamental to ensure the normal and safe operation of the equipment.

Of course, for the equipment, the normal operation method is also an important part to ensure the normal operation of the equipment and improve the service life of the equipment.

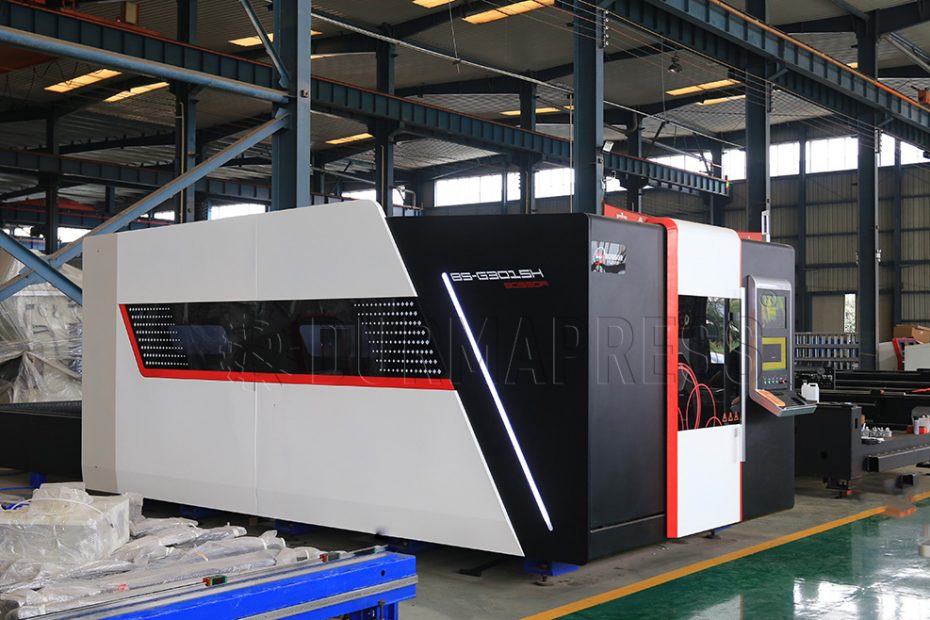

The same is true for laser cutting machine, laser cutting machine power supply is one of the very important parts of the equipment BS3015T-3000W Full Covered Sheet Laser Cutting ,

improper use will not only affect the normal operation of the equipment, but also easy to cause damage to the power supply,

affect the normal production. So how do we use to protect the life of the power supply to a greater extent?

1, laser cutting machine in the cutting, try to set according to the parameters of the cutting table, such as cutting speed, thickness,

so as not to exceed the standard range, damage the normal service life of the power supply;

2. Clean and maintain the machine regularly to reduce the operating pressure of the machine;

3, each cutting, to check the machine, check whether the grounding is good, to ensure the full use of laser cutting machine power;

4, try not to hang for a long time arc and perforation, in order to improve the service life of wearing parts;

5, sometimes the external voltage will be unstable, so it is necessary to equip the equipment with voltage regulator to ensure a stable voltage supply;

6, operators in the process of operation, careful maintenance and proper use, to ensure the normal operation of the machine, to ensure the quality of cutting.