features

- German-made core components for stable performance.

- Cutting head with flexible focal length adjustment.

- Automated features for efficient pipe processing.

- Intelligent temperature control for stability in extreme climates.

- Dual-temperature control cold water system for reliability.

- Automatic discharging system minimizes manual work.

- Self-centering chuck design for versatile tube processing.

- Capable of handling various tube shapes and sizes.

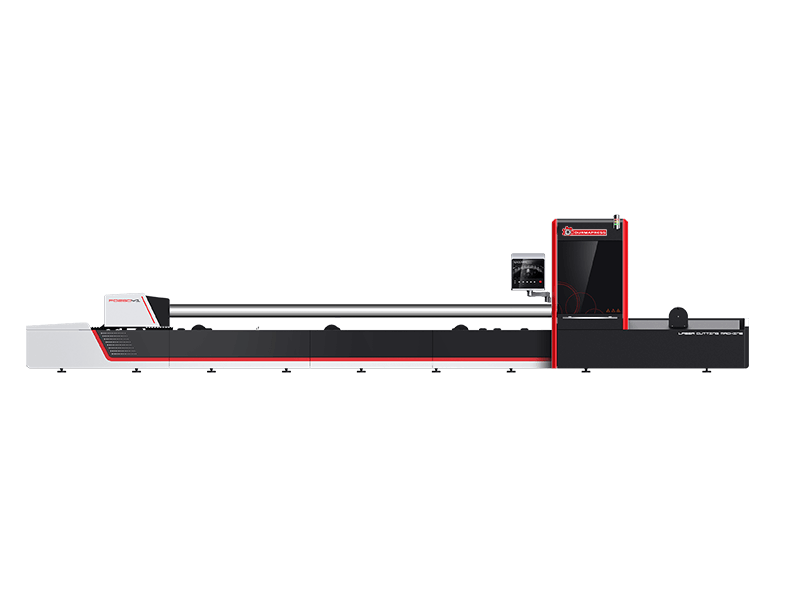

Laser Power

1000 - 30000W

Diameter

180-320mm

Length

3-6 meters

OPTIONAL Component

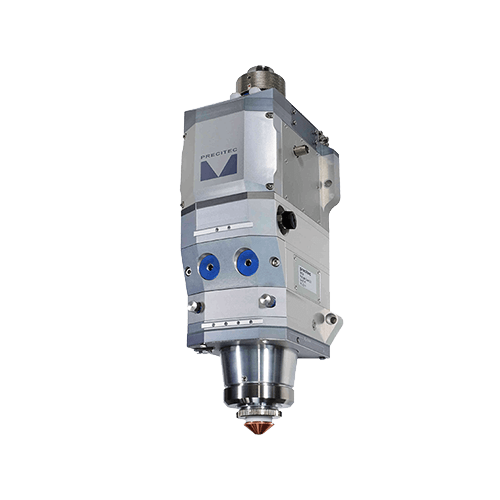

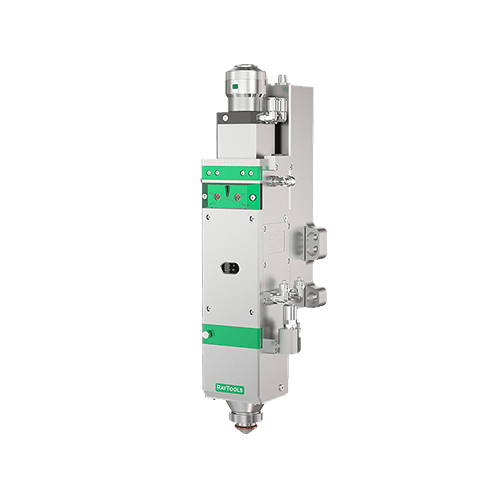

Laser cutting head

Customize The Controller For Your Fiber Laser Cutting Machine

precitec

Precitec offers suitable solutions for all your requirements and machine concepts. Flat materials of various thicknesses made of steel, stainless steel, aluminium, or non-ferrous metals are processed.

Raytools

Modular design with easy maintenance. Dual water cooling circuits. Auto focus to reduce human intervention and improve piercing and cutting efficiency.

WSX

This cutting head is mainly used for laser below 2000W. The internal structure of the laser head is completely sealed to avoid the contamination of the optical lens.

OPTIONAL Component

Laser Source

Customize The Controller For Your Fiber Laser Cutting Machine

IPG laser

IPG Photonics is renowned for its high-quality, stable, and long-lasting fiber lasers, backed by innovative technology.

raycus laser

Raycus offers cost-effective fiber lasers with excellent performance and a wide range of applications, ideal for various precision machining tasks.

max laser

Max provides high-performance fiber lasers with a diverse product line, ensuring superior quality, reliability, and comprehensive technical support.

STANDARD Component

Other Components

Every part can ensure a long service life and reduce production costs.

Machine Frame

Durmapress machine body feature a robust mono-block frame made from high yield steel, ensuring enduring accuracy and reliability. Each frame is tempered and backed by a 15-year warranty.

Laser Source

Laser sources play a pivotal role in laser cutting machines, offering numerous advantages. They provide high precision and accuracy, enabling the cutting of complex geometries with fine details.

Automatic Chuck

Automatic chuck devices are used to position and clamp the pipes to be processed. It can clamp the pipe quickly and accurately and ensure its position is stable so that the accurate position and direction of the pipe can be maintained during laser cutting.

CNC controller panel

The CNC control panel allows the operator to set and adjust processing parameters such as laser power, cutting speed, focal length, etc. The setting of these parameters is crucial to achieve cutting, engraving and other processing tasks of different materials and thicknesses.

tube supporter

The main function of the tube supporter is to ensure that the pipe remains stable during the cutting process and to avoid cutting errors or workpiece damage caused by movement or shaking of the pipe.

cutting head

The cutting head is the component used in the laser pipe cutting machine to focus and control the laser beam. It is responsible for accurately irradiating the laser beam onto the surface of the pipe for cutting.

optional Component

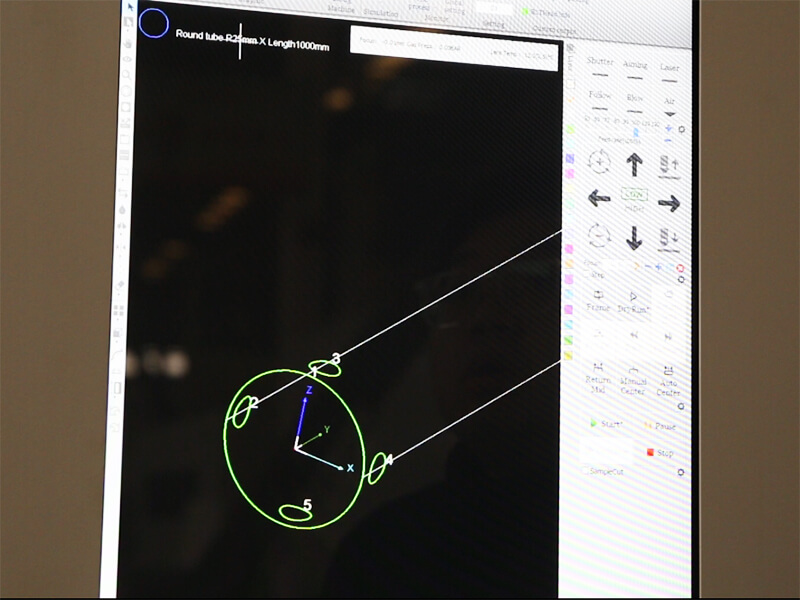

CNC controller system

CypCut Software

High-performance open loop laser control system

- Particular air pressure calibration function

- Multistage punch

- Laser energy control

- Adaptive edge search

- Leapfrog function

- Automatic corner acceleration and deceleratio

- Fly-cutting

- Mechanical precision compensation

Optionl device

Automatic pipe loading machine

Loading pipe unit

- Standard pipe diameter ф20-360mm (optional)

- Standard pipe length 6/9/12m

- PLC whole machine control

- Maximum Loading: Max to 6000kg

Get a quote now!

Get more details about DURMAPRESS®’s BS-D Series Fiber Laser Cutting Machine

Materials and power

Actual demand is also affected by cutting speed, cutting quality, work efficiency and other factors. Therefore, when choosing a laser cutting machine power, please consult us to ensure that it meets the requirements of your specific application.

- Low Power (500W - 2000W): Suitable for thin sheet metal cutting, such as stainless steel and mild steel up to 6mm thickness, and non-metallic materials like plastics and thin wood.

- Medium Power (2000W - 6000W): Offers increased cutting capabilities for thicker metal sheets, such as stainless steel up to 12mm thickness and mild steel up to 16mm thickness.

- High Power (6000W and above): Designed for heavy-duty cutting tasks, including thick metal sheets (up to 30mm or more) and high-speed cutting of thin to medium-thickness materials.

Why Choose BS-H Series?

1

High Cutting Precision

It is equipped with advanced laser cutting technology. This precision is crucial for industries requiring intricate designs or tight tolerances.

2

Versatility

It is designed to cut a wide range of materials, including different types of metals (such as steel, stainless steel, and aluminum).

3

Efficiency and Productivity

With its high cutting speed and efficiency, it can streamline production processes and increase productivity.

durmapree factory

Watch the Video

Manufacturer of cutting-edge metal processing equipment

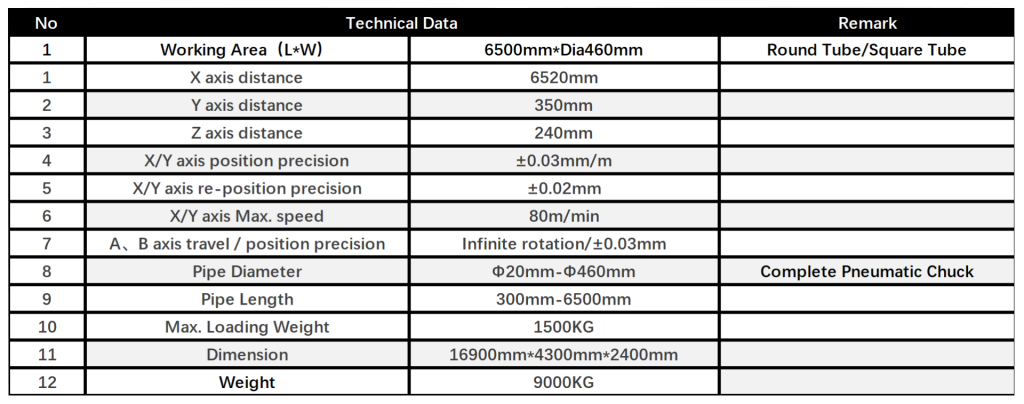

Product parameters

related products

BS-E SERIES

FULL-COVERED Plate&TUBE Fiber Laser Cutting Machine

BS-G Series

OPEN TYPE Tube & Plate Fiber Laser Cutting Machine

Contact us

Location

High Tech Industrial , Bowang Town, Maanshan, Anhui, China

Our Hours

7/24

Follow Us