Development of Press Brake

Press brakes can be divided into mechanical press brakes and hydraulic press brakes according to their transmission forms. At present, mechanical press brakes have been replaced by hydraulic press brakes. The advantages of hydraulic press brakes are that they have a larger working stroke, can generate maximum nominal force at any point of the stroke; bending stroke, pressure, and speed can be adjusted, easy to realize CNC; can achieve rapid approach, slow bending, in line with the technological requirements of workpiece bending; using multi-cylinder synchronous system greatly improves the bending accuracy, and realizes multi-machine linkage of press brakes, expanding the technological range of press brakes. CNC hydraulic sheet metal press brake is the earliest metal sheet processing machine tool, with the most extensive application and the most domestic production enterprises, it has developed from the early 3-axis to the current 8-axis control, and it is matched with loading and unloading robots and bending robots to form CNC bending units.

The earliest press brakes required manual operation, which was very inconvenient, and it was difficult to guarantee the bending accuracy, and the production efficiency was low. Later, with the popularization and maturity of electronic technology and computer application technology, a large number of hydraulic press brakes based on PLC control system emerged, realizing high-precision bending process. This system of press brakes is called CNC press brake, which has gradually replaced manually operated hydraulic press brakes, accurately controlling bending accuracy, reducing errors, reducing costs, and improving efficiency.

CNC press brakes are widely used in various industries such as aircraft, shipbuilding, automotive, and electrical industries. There are hundreds of manufacturers in China producing various types of press brakes. However, the development level of press brakes in China still lags behind that of foreign countries.

The types of press brakes vary widely, including hydraulic press brakes, CNC press brakes, bidding press brakes, condenser press brakes, manual press brakes, busbar press brakes, shear plate press brakes, and dozens of others, with widely diverse applications.

In the 1980s, there was significant progress in the application of CNC technology in press brakes. Almost all press brakes imported from abroad to China were equipped with advanced CNC systems. Currently, the CNC systems of domestic press brakes are mostly imported and then customized with Chinese language prompts and CAD/CAM graphic functions.

Press brakes are mainly used for processing metal sheets. With various molds, metal sheets can be bent into the desired shapes for users. When equipped with corresponding equipment, they can also be used for punching. Press brakes are widely used in factories producing aircraft, ships, automobiles, and electrical appliances, boasting high production efficiency. The mainstream transmission method of press brake sliders both domestically and abroad is hydraulic transmission, which features powerful transmission force, suitable for large-scale machines, and has a high cost-effectiveness ratio.

As CNC press brakes continue to develop, the bending dies equipped on press brakes also continue to evolve. Looking at the development history of bending dies on CNC press brakes, from the late 19th century to the mid-20th century, high-speed steel was the main material for bending dies. In 1927, Germany first developed hard alloy CNC bending die materials, which were widely used. In the 1950s, Sweden and the United States separately synthesized artificial diamonds, ushering in an era dominated by superhard materials for cutting CNC bending dies. In the 1970s, people used high-pressure synthesis technology to synthesize polycrystalline diamond (PCD), solving the problems of scarcity and high prices of natural diamonds, thus expanding the application range of CNC bending dies to aviation, aerospace, automotive, electronic, stone, and other fields.

Observing the development of China's manufacturing industry from a global perspective, it is evident that China's manufacturing industry has developed rapidly in recent years. For the CNC press brake die industry, this signifies a significant market opportunity. However, against this backdrop, China's low-level manufacturing costs are a recognized fact. From the perspective of labor productivity, there is statistical data showing that China's labor productivity is approximately 3-5 times lower than that of developed countries such as Germany, the United States, and Japan. In such a large market with low labor productivity, coupled with the continuous progress and development of manufacturing technology, it poses both opportunities and challenges for the CNC press brake die industry. The demand from the market for CNC press brake dies is not only in terms of quantity but also in terms of quality improvement.

Classification of Press Brakes

Press brakes are classified into manual press brakes, hydraulic press brakes, and CNC press brakes. Manual press brakes are further divided into mechanical manual press brakes and electric manual press brakes. Hydraulic press brakes are categorized based on synchronization into shaft synchronization, mechanical-hydraulic synchronization, and electro-hydraulic synchronization. Hydraulic press brakes can also be classified based on motion into up-stroking and down-stroking types.

The Function of Press Brakes

Sheet metal press brakes are capable of V-grooving stainless steel sheets, iron sheets, copper sheets, and other material sheets. Advanced sheet metal grooving machines, when equipped with specific attachments, can also perform tasks such as polishing, buffing, and wire drawing on metal sheets and profiles. They are primarily used in the sheet metal industry for bending and shaping, such as in automotive manufacturing, doors and windows production, and steel structure fabrication.

Basic Knowledge of Bending

Bending of sheet metal refers to the process of changing the angle of the sheet or workpiece, such as bending it into V-shapes or U-shapes. Generally, there are two methods of sheet metal bending: mold bending and press brake bending. Mold bending is suitable for complex structures, small volumes, and mass production of sheet metal structures, while press brake bending is suitable for processing larger-sized structures or when the production volume is not too high. These two bending methods have their own principles, characteristics, and applicabilities.

Bending with Press Brake

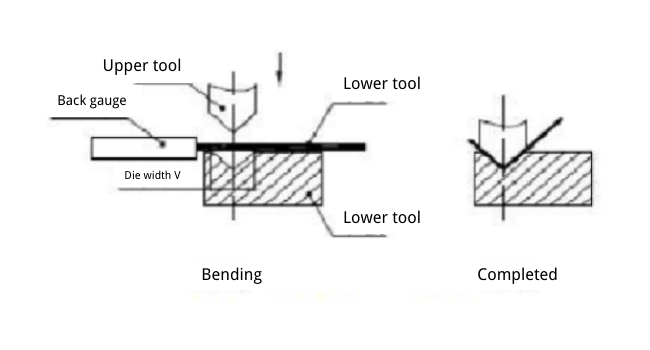

Press brakes are divided into conventional press brakes and CNC press brakes. When high precision is required, and for irregularly shaped sheet metal bending, CNC press brakes are generally used. The basic principle is to utilize the bending blade (upper die) and V-shaped groove (lower die) of the press brake to bend and shape sheet metal components.

Bending Blade (Upper Die)

The form of the bending blade is shown in Figure 1-3. During processing, it is primarily selected according to the shape requirements of the workpiece.

The lower die is generally a V-shaped die with a width of (6-8)t (where t is the material thickness).

There are many factors that affect bending processing, mainly including the radius of the upper die's arc, material, material thickness, lower die strength, and the size of the die orifice. In Figure 1-3, the left side shows the upper die, and the right side shows the lower die.

Basic Principles of Bending Sequence

Bend from the inside to the outside.

Bend from small to large.

Bend special shapes first, then general shapes.

Ensure that the preceding forming process does not affect or interfere with subsequent processes.

Bending Radius

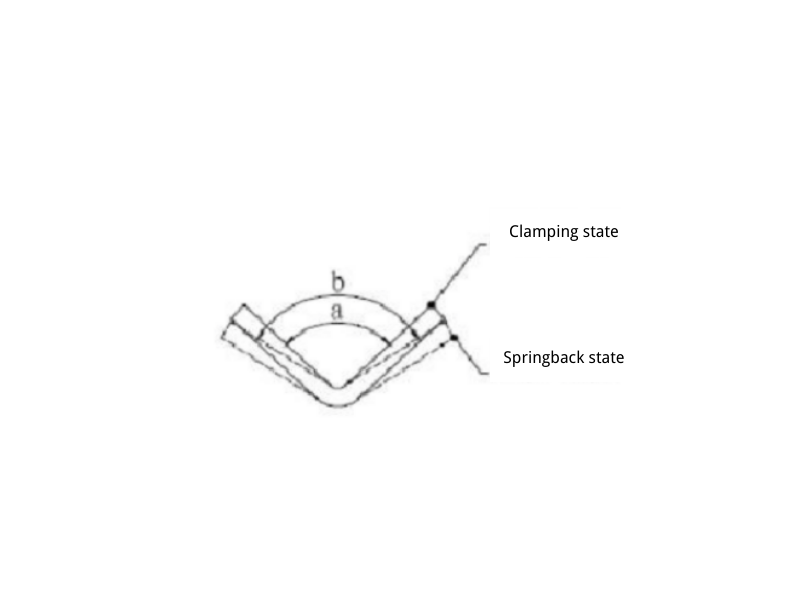

When bending sheet metal, there should be a bending radius at the bending point. The bending radius should not be too large or too small and should be appropriately chosen. A radius that is too small can cause cracking at the bend, while a radius that is too large can make the bend prone to springback.

Bending Springback

Compression State

Springback State

Figure 1-5: Schematic Diagram of Bending Springback

Springback Angle Δa = b - a

b - actual angle of the workpiece after springback

a - angle of the die

For secondary or higher-order bends, interference between the bent workpiece and the tool often occurs, as shown in Figure 1-6. The black portion represents the interfering part. This prevents the completion of the bend or may cause bending deformation due to interference during bending.

One-Time Flattening Edge

Method for one-time flattening edge: As shown in Figure 1-8, first bend the sheet metal at a 30-degree angle using a 30-degree bending blade, then flatten the bent edge.

The Future of Press Brake Machines

From the current perspective, the development trend of CNC press brake systems mainly focuses on three aspects: performance, functionality, and system architecture. Specifically, in terms of performance: high precision, high speed, high efficiency, flexibility, multi-axis control, open software and hardware, and intelligence.

Functionality: Graphical user interface, visualization of scientific calculations, diverse interpolation and compensation, high-performance built-in PLC.

Performance:High Precision, High Speed, High Efficiency:

Efficiency and quality are key performance indicators of advanced manufacturing technology. Utilizing technologies such as high-speed CPU chips, RISC chips, multi-CPU control systems, high-resolution detection elements, AC digital servo systems, matching electric spindles, linear motors, etc., can greatly improve efficiency, enhance product quality and grade, shorten production cycles, and enhance market competitiveness. In the coming years, super-precision CNC press brakes are evolving towards precision, high speed, intelligence, and nanotechnology, converging into a new generation of CNC press brake machine tools.

Flexibility:The CNC press brake system adopts a new generation of modular design, with a wider range of functions and stronger reliability, to meet the needs of different users. The same group control system can automatically adjust the information flow dynamically according to different production processes, exerting the functions of the group control system.

Multi-Axis Control:With multi-axis linkage processing, after clamping the workpiece on a CNC press brake machine tool, automatic tool change, rotating spindle head, rotating worktable, and other operations can be performed to complete complex processing with multiple processes and surfaces. This not only ensures high surface finish but also greatly improves efficiency.

Open Software and Hardware:Users can perform secondary development on the software of the CNC press brake system according to their own needs, and their usage scope is no longer restricted by the manufacturer.

Graphical User Interface

The user interface is the dialogue interface between the CNC press brake system and the user. The graphical user interface should be suitable for various users, including non-professional users. Operations can be performed through windows and menus, enabling functions such as graphical simulation, dynamic tracking, simulation, and rapid programming.

Scientific Calculations Visualization: Enhancing CNC Precision

In today's machining industry, information exchange transcends traditional textual and verbal forms, with the integration of visual data such as graphics, images, and animations. Visualization technology finds extensive application in CAD/CAM, parameter automation, tool compensation, and real-time display, enhancing the understanding and efficiency of the machining process. The diversification of interpolation methods, including linear, circular, and polynomial, alongside various compensation functions such as backlash and temperature compensation, ensures precision and accuracy in CNC operations. Moreover, the integration of high-performance PLCs into CNC press brake systems facilitates direct programming through ladder diagrams or high-level languages, supporting seamless online debugging and editing modifications, empowering users to tailor applications to their specific needs.

System Architecture Advancements for CNC Press Brakes

In response to the evolving needs of modern industrial practices, the system architecture of CNC press brakes is undergoing significant enhancements. Integration is achieved through the utilization of highly integrated CPUs, RISC chips, and large-scale programmable integrated circuits, bolstering the integration density and operational speed of the system while improving overall reliability. Modularization further standardizes and streamlines CNC press brake systems by integrating components such as CPUs, memory, position servos, and communication interfaces into standardized series products, catering to different grades of system requirements. As the modern industrial revolution progresses, the widespread adoption of CNC press brakes is anticipated, driving continuous advancements towards user-friendly interfaces, enhanced bending accuracy, and increased efficiency, thereby revolutionizing the entire mechanical processing industry.

About Us

Durmapress specializes in designing, manufacturing and selling various metal processing equipment, including bending machines, shears, punches, laser cutting machines, etc. The company was founded in 2000. With years of experience and technology accumulation. DurmaPress has become one of the well-known brands in China's metal processing machinery industry.

Contact Us

Recent Posts

Categories

Follow Us

Contact us for more information

If you have any information about our products, please contact us and we will reply within 24 hours.