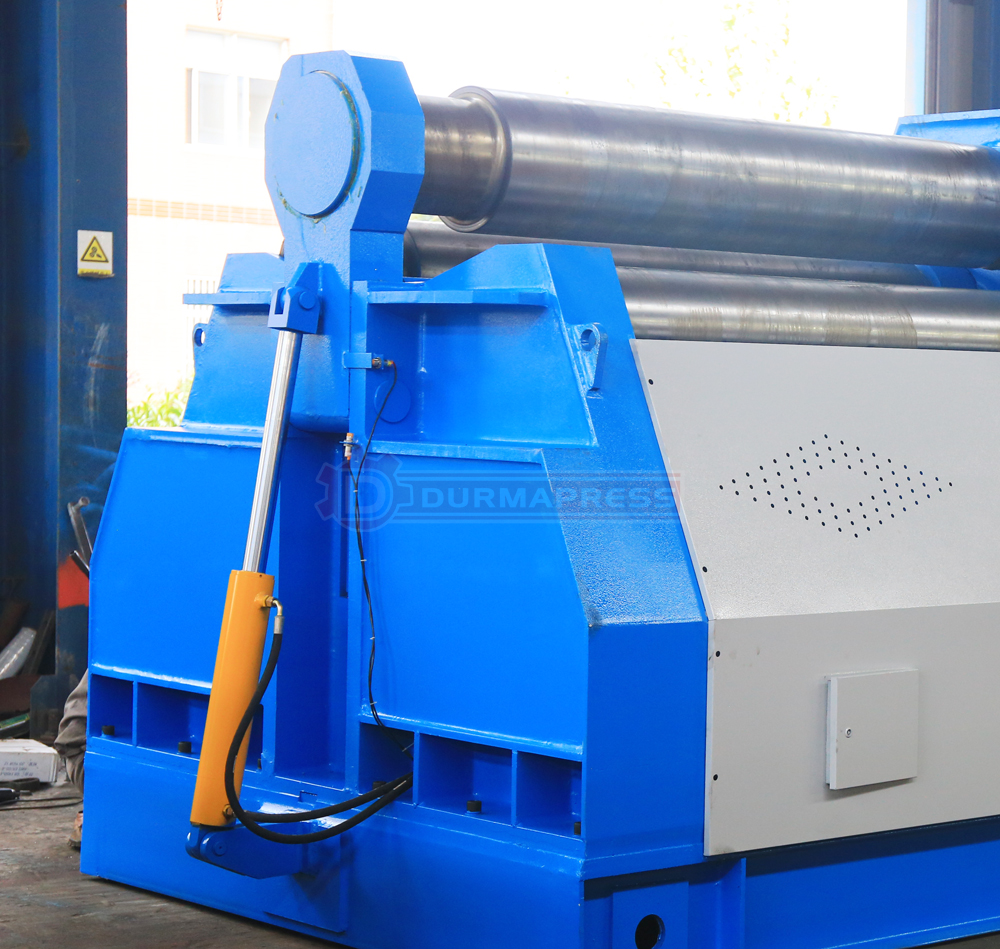

4-Roller Plate Bending Machine

General Features

1. Accurate, ease of operate, fastest roll bendings

2. Flat zone of the sheet edges is minimised

3. Pre-bending, conical bending and ellipse bending can be done easily

4. Double pre-bends(both ends) in one pass

5. Hydraulic and electrical system have been safeguarded from overloads and require minimum maintenance

6. Hydraulic and electrical components are modular and designed according to world standards

7. The sheet is controlled by tighteding of top and bottom rolls

8. Most suitable bending operation for CNC applications

9. More efficient for cycle times

10. User friendly operations without dependence to operator competence

11. Feeding on the order sheet to be completed by the prebend Circle, the smaller circular process

12. Volume in to the curved, cylindrical, conical workpiece

13. Driving for mechanical transmission, hydraulic transmission for the two movements under the roller

2. Flat zone of the sheet edges is minimised

3. Pre-bending, conical bending and ellipse bending can be done easily

4. Double pre-bends(both ends) in one pass

5. Hydraulic and electrical system have been safeguarded from overloads and require minimum maintenance

6. Hydraulic and electrical components are modular and designed according to world standards

7. The sheet is controlled by tighteding of top and bottom rolls

8. Most suitable bending operation for CNC applications

9. More efficient for cycle times

10. User friendly operations without dependence to operator competence

11. Feeding on the order sheet to be completed by the prebend Circle, the smaller circular process

12. Volume in to the curved, cylindrical, conical workpiece

13. Driving for mechanical transmission, hydraulic transmission for the two movements under the roller

Why Choose BS3015D Rolling Machine

►Liner guideway system, reliable and endurable.

►Electronic balance synchronization control system(accuracy ± 0.15mm).

►Double power roller with 2 gearbox and 2 hydraulic motor.

►Surface of roller with heat treatment, which hardness can be HB260-300.

►Hydraulic system to prevent overload.

►Automatic lubrication system.

►Lower voltage control system.

►Automatic alarm system for lower oil level and filter clogged.

►Safety stop system, to stop all moving parts of the whole machine.

Components

Standard equipment:

- Linear guides for roll motion (RGS)

- 4 independent bearings supporting the lower rolls (MCS)

- Bearing seats with double width (WHS)

- Electronic synchronisation of roll parallelism (EPS)

- Hardened and polished rolls

- SIEMENS numerical control

- Mobile wheel mounted control console

- Conical device

- Centralised manual lubrication (pump)

- Emergency barrier around the machine

- CE certified machine

Optional features:

- Side motorised rolls

- Automatic loading and unloading systems

- Motorised feeding table

- Automatic ejector

- Central and side supports

- Provision for hot rolling

- Version with planetary guides (4HEP)

- Integrated welding system

- Special colours

Main Components

PLC Controller

- Special bending aircraft , numberical control

- HMI ( Human machine interface ) Intelligent operation

- Self-compensation , single operate , high efficiency , safe and convenient

- Many models for choice , economic numberical control model

, TC Computerized numberical control .

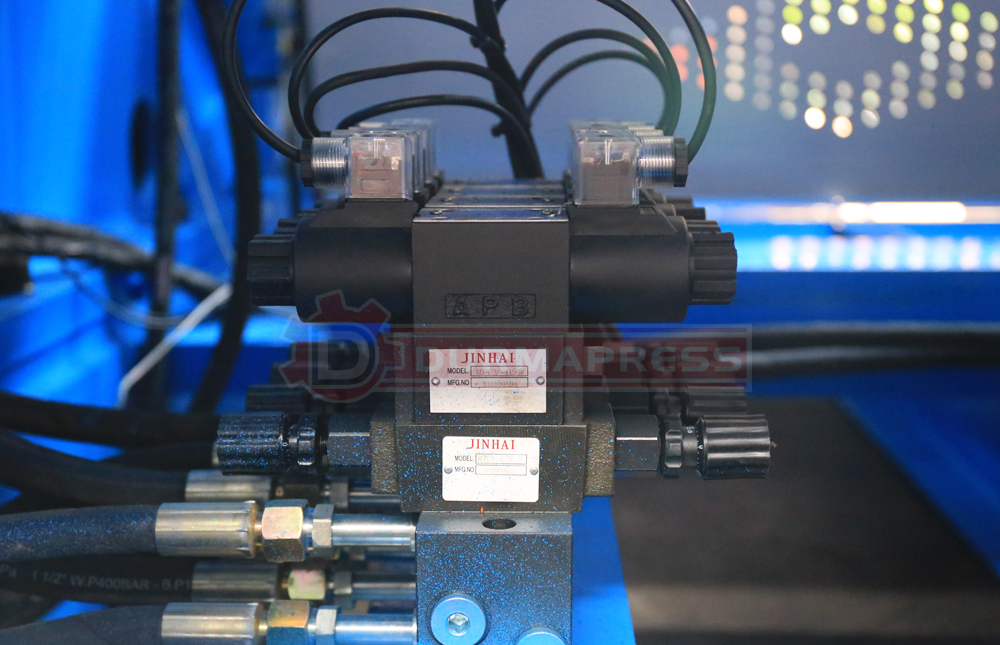

Oil Cylinder

- Pump Station :ChangYuan,China Options: Sunny,USA

- Valve : Yuken,Japan

Hydraulic System

- Through exclusive technology, it can developcones as easily as competitive machines can de-velop cylinders.

lt eliminates scarring on the surface of shell or rolland also eliminates, in most cases, the need forgrinding the lamination (bullnosing) on the minordiameter edge.

Yuken valve made in Japan.

Release Device

Hydraulic drop-end for easy removal offinished ferrule.

Product Introduction Video

CNC Rolling Machine

This machine is reliable and effective. The parallelism of the side rolls is controlled by a torsion bar system that connects to both ends of the side roll, eliminating the disadvantage of extra encoders and special hydraulic balancing valves. The two central rolls are driven by hydraulic motors and high efficiency planetary gearboxes coupled directly on the rolls. The MG solution, with rolls assembled on sealed bearings and without secondary components, reduces the dispersions of the applied force generated by the frictions of the various components (typical in synchronization systems used in other bending machines).

Gallery

Technical Data

| Name | W12-4*3000 | W12-6*2000 | W12-6*2500 | W12-6*3000 | W12-8*2000 | W12-8*2500 | W12-8*3000 | W12-10*2000 | W12-10*2500 | W12-10*3000 | W12-12*2000 | W12-12*2000 | W12-12*3000 | W12-16*2000 | W12-16*2500 | W12-16*3000 | W12-20*2000 | W12-20*2500 | W12-20*3000 | W12-25*2000 | W12-25*2500 | W12-25*3000 | W12-30*2000 | W12-30*2500 | W12-30*3000 | W12-35*2000 | W12-35*2500 | W12-35*3000 | W12-40*2500 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Max. Bending Thickness (mm) | 4 | 8 | 6 | 6 | 8 | 8 | 8 | 10 | 10 | 10 | 10 | 10 | 12 | 16 | 16 | 16 | 20 | 20 | 20 | 25 | 25 | 25 | 30 | 30 | 30 | 35 | 35 | 35 | 40 |

| Pre-Bending Thickness (mm) | 3 | 5 | 5 | 5 | 6.5 | 6.5 | 6.5 | 8 | 8 | 8 | 8 | 8 | 10 | 13 | 13 | 13 | 16 | 16 | 16 | 20 | 20 | 20 | 25 | 25 | 25 | 28 | 28 | 28 | 32 |

| Roller Working Length (mm) | 3050 | 2050 | 2550 | 3100 | 2050 | 2550 | 3100 | 2050 | 2550 | 3100 | 3100 | 3100 | 3100 | 2050 | 2550 | 3100 | 2050 | 2550 | 3100 | 2050 | 2550 | 3100 | 2050 | 2550 | 3100 | 2050 | 2550 | 3100 | 2550 |

| Plate Yeild Limit(Mpa) | 245 | 245 | 245 | 245 | 245 | 245 | 245 | 245 | 245 | 245 | 245 | 245 | 245 | 245 | 245 | 245 | 245 | 245 | 245 | 245 | 245 | 245 | 245 | 245 | 245 | 245 | 245 | 245 | 245 |

| Top Roller Diameter(mm) | 190 | 190 | 210 | 230 | 210 | 230 | 270 | 230 | 270 | 300 | 300 | 300 | 330 | 300 | 330 | 360 | 330 | 360 | 390 | 360 | 390 | 430 | 390 | 430 | 460 | 430 | 460 | 510 | 510 |

| Bottom Roller Diameter(mm) | 170 | 170 | 190 | 210 | 190 | 210 | 250 | 210 | 250 | 270 | 270 | 270 | 300 | 270 | 300 | 330 | 300 | 330 | 360 | 330 | 360 | 390 | 360 | 390 | 420 | 390 | 420 | 460 | 460 |

| Side Roller Diameter (mm) | 150 | 150 | 170 | 0 | 170 | 190 | 210 | 190 | 210 | 220 | 220 | 220 | 240 | 220 | 240 | 250 | 240 | 250 | 300 | 250 | 300 | 330 | 300 | 330 | 360 | 330 | 360 | 390 | 390 |

| Main Motor Power (KW) | 4 | 4 | 5.5 | 7.5 | 5.5 | 7.5 | 11 | 7.5 | 11 | 11 | 11 | 11 | 11 | 11 | 11 | 15 | 11 | 15 | 18.5 | 15 | 18.5 | 22 | 18.5 | 22 | 30 | 22 | 30 | 30 | 37 |

| Length (mm) | 3650 | 4650 | 5150 | 60 | 4650 | 5250 | 5700 | 4770 | 5270 | 5700 | 5700 | 5700 | 5770 | 4700 | 5550 | 6300 | 4700 | 5800 | 6500 | 5300 | 6250 | 7000 | 5000 | 6500 | 7300 | 6000 | 6800 | 7600 | 7100 |

| Width (mm) | 1300 | 1300 | 1450 | 1450 | 1420 | 1500 | 2130 | 1420 | 1420 | 1500 | 1500 | 1500 | 1900 | 1500 | 1840 | 2000 | 1900 | 2000 | 2250 | 2000 | 2160 | 2300 | 2160 | 2300 | 2600 | 2300 | 2600 | 2800 | 2800 |

| Height (mm) | 1400 | 1400 | 1400 | 1400 | 1400 | 1400 | 2000 | 1400 | 1400 | 1500 | 1500 | 1500 | 1880 | 1500 | 1820 | 2050 | 2000 | 2050 | 2550 | 2050 | 2350 | 2500 | 2350 | 2500 | 2700 | 2500 | 2700 | 2900 | 2900 |

| Weight (KG) | 4800 | 4800 | 5800 | 7000 | 5600 | 6300 | 9500 | 5800 | 6500 | 8800 | 8800 | 8800 | 13500 | 7500 | 12000 | 17000 | 12000 | 15000 | 23000 | 14000 | 22500 | 30000 | 21000 | 27000 | 33000 | 25000 | 31000 | 38500 | 35000 |