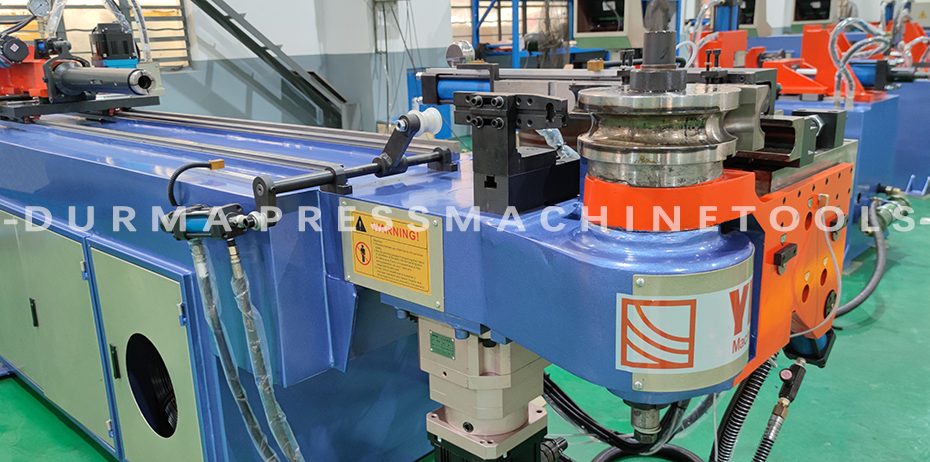

The three DIMENSIONAL automatic pipe bender is an innovative product with high high-tech content, which has the advantages of high precision of repeated positioning, good reliability, simple operation, convenient maintenance and moderate price.

This machine can fully meet the high, medium and low gear all kinds of bus body frame bending components of large, small batch production.

It is a necessary special equipment for bus production enterprises to improve production technology.

The control system of three-dimensional automatic pipe bender is mainly composed of human-machine interface (HMI), programmable controller (PLC), three sets of servo motors,

oil cylinders and cylinders, etc. The human-machine interface (HMI) with formula function can store hundreds of kinds of process parameters of the workpiece and realize man-machine dialogue.

PLC using Panasonic FP-X, can achieve four axis positioning and two groups of interpolation function at the same time, to meet the complex control requirements of three-dimensional pipe bender control system.

And the servo motor in the equipment all adopt the domestic advanced ac servo motor, its function is to realize the two axes (bending axis and rotation axis of rotation Angle control and realize a shaft (feed axis) feed control, the feed axis and bending axis bending has been accomplished by linear interpolation function, two axis by the bending Angle of displacement, rotation axis rotate positioning according to the instructions. In addition, the solenoid valve with the cylinder, cylinder is used to realize the bending power, such as the main clip, the auxiliary clip, the material clip, the core rod, the trustege, etc.

The servo motor plays a vital role in this equipment. The good performance of the servo is the key to the normal operation of the whole equipment. By adjusting the parameters, the servo motor can run in the best state to ensure the normal operation of the whole equipment.

, due to the different transmission mechanism to ensure the speed and precision of each shaft need proper regulation required one revolution of the final output pulse number, but realize interpolation of two axes are exactly the same, need to ensure that the pulse number by setting of servo motor electronic gear ratio can easily solve the problem. Because there are hundreds of species of processed workpiece, the number of elbow each artifact can be specific to more than 20, because each elbow related data needs, in turn, calls, to simplify the procedure can consider when writing a call by the index register these data stored in the man-machine interface formula, then after a series of real number operation into pulse number.

Due to the different types of workpiece processed by pipe bender, the allowance of linear feed direction in the final station is often very small. In order to prevent the material clip from colliding with the secondary clip, each action needs to be processed in a specific combination order.